Aluminum Nitride — AlN

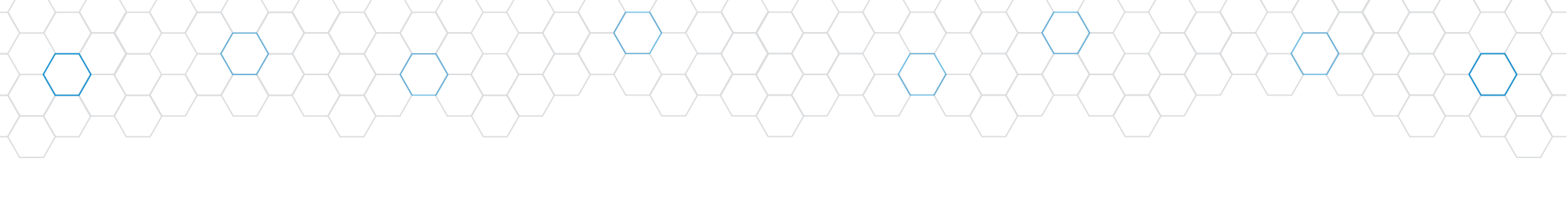

Combining excellent thermal conductivity and high thermal shock resistance with superior electrical insulation, aluminum nitrides provide electrical insulation while also dissipating heat effectively in applications where other ceramics are prone to thermal shock. Typical applications include high temperature, high-intensity light emitting diodes (LEDs), and semiconductor manufacturing equipment applications.

Primary Features

- Thermal conductivity

- Thermal stability and shock resistance

- Electrically insulative

- Plasma resistance

Applications

- Semiconductor manufacturing equipment components

- Electronic substrates

- Heater components

- Transportation components

![]()

Materials

- KMT-AN180 — 96% AlN (gray)

- KMT-AN200 — 96% AlN (gray)

- KMT-AN220 — 97% AlN (beige)

Material Properties for KemaTek Aluminum Nitrides

| Properties | Units | Test | Aluminum Nitride — AlN | ||

| Material Name | KMT-AN180 | KMT-AN200 | KMT-AN220 | ||

| Color | Gray | Gray | Beige | ||

| Primary Material Content | 96% AlN | 96% AlN | 97% AlN | ||

| Characteristics | High thermal conductivity, excellent thermal shock and plasma resistance | ||||

| Applications | Heat dissipating components, plasma-resistant components | ||||

| Bulk Density | g/cc | ASTM-C20 | 3.30 | 3.30 | 3.28 |

| Water Absorption | % | ASTM-C373 | 0 | 0 | 0 |

| Vickers Hardness (Load 500 g) | GPa | ASTM-C1327-03 | 10.0 | 9.5 | 9.0 |

| Flexural Strength | MPa | ASTM-C1161-02c | ≥350 | ≥325 | ≥280 |

| Compressive Strength | MPa | ASTM-C773 | 2500 | 2500 | — |

| Young’s Modulus of Elasticity | GPa | ASTM-C1198-01 | 320 | 320 | 320 |

| Poisson’s Ratio | — | ASTM-C1198-01 | 0.24 | 0.24 | 0.24 |

| Fracture Toughness | MPa * m12 | ASTM-C1421-01b (Kevron notched beam) | — | — | — |

| Coefficient of Linear Thermal Expansion, 40-400 ℃ | x 10-6/℃ | ASTM-C372-94 | 4.8 | 4.6 | 4.5 |

| Thermal Conductivity, 20℃ | W/(m • K) | ASTM-C408-88 | 180 | 200 | 220 |

| Specific Heat | J/(Kg • K) x 103 | ASTM-E1269 | 0.74 | 0.74 | 0.76 |

| Thermal Shock Resistance | ℃ | Note 1 | — | — | — |

| Volume Resistivity, 20℃ | Ω • cm | ASTM-D257-99 | ≥1014 | ≥1014 | ≥1013 |

| Dielectric Strength | KV/mm | ASTM-D149-97 | ≥15 | ≥15 | ≥15 |

| Dielectric Constant, 1 MHz | — | ASTM-D150-98 (1 MHz) | 9.0 | 8.8 | 8.6 |

| Loss Tangent | (x 10-4 | ASTM-D150-98 (1 MHz) | 5.0 | 5.0 | 3.0 |

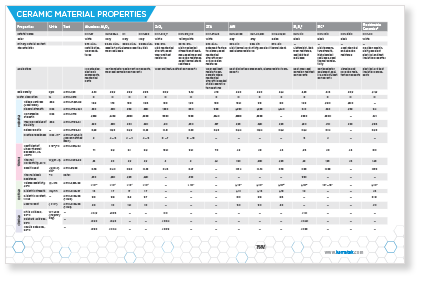

Ceramic Materials Properties Chart — All Materials — PDF, 128K

For more information or to get a quote on your next refurbishment project, please contact us.