Zirconia Toughened Alumina — ZTA

Zirconia toughened alumina is a composite ceramic material comprising alumina and zirconia. This material provides added strength and thermal shock resistance over alumina but at less cost than zirconia.

ZTA composites are commonly used in structural applications, cutting tools, and medical applications. Additionally, ZTA composites feature high strength, fracture toughness, elasticity, hardness, and wear resistance.

Primary Features

- Improved strength over alumina

- Impact resistance

- Thermal resistance

- Improved hardness

Applications

- Wear components

- Pump components

- Valves

- Impellers

- Particulate abrasion components

Materials

- KMT-ZTA85 — 85% AlN (white)

Material Properties for KemaTek Zirconia Toughened Alumina

| Properties | Units | Test | Zirconia Toughened Alumina |

| Material Name | KMT-ZTA85 — 85% Al2O3 (white) | ||

| Color | white | ||

| Primary Material Content | 85% Al2O3 | ||

| Characteristics | Enhanced fracture toughness, good mechanical strength, wear, and corrosion resistance | ||

| Applications | Wear and heat resistant components where mechanical strength is needed at high operating temperatures | ||

| Bulk Density | g/cc | ASTM-C20 | 4.15 |

| Water Absorption | % | ASTM-C373 | 0 |

| Vickers Hardness (Load 500 g) | GPa | ASTM-C1327-03 | 16.0 |

| Flexural Strength | MPa | ASTM-C1161-02c | 500 |

| Compressive Strength | MPa | ASTM-C773 | 2580 |

| Young’s Modulus of Elasticity | GPa | ASTM-C1198-01 | 337 |

| Poisson’s Ratio | — | ASTM-C1198-01 | 0.23 |

| Fracture Toughness | MPa * m12 | ASTM-C1421-01b (Kevron notched beam) | — |

| Coefficient of Linear Thermal Expansion, 40-400 ℃ | x 10-6/℃ | ASTM-C372-94 | 7.0 |

| Thermal Conductivity, 20℃ | W/(m • K) | ASTM-C408-88 | 24 |

| Specific Heat | J/(Kg • K) x 103 | ASTM-E1269 | — |

| Thermal Shock Resistance | ℃ | Note 1 | — |

| Volume Resistivity, 20℃ | Ω • cm | ASTM-D257-99 | — |

| Dielectric Strength | KV/mm | ASTM-D149-97 | — |

| Dielectric Constant, 1 MHz | — | ASTM-D150-98 (1 MHz) | — |

| Loss Tangent | (x 10-4 | ASTM-D150-98 (1 MHz) | — |

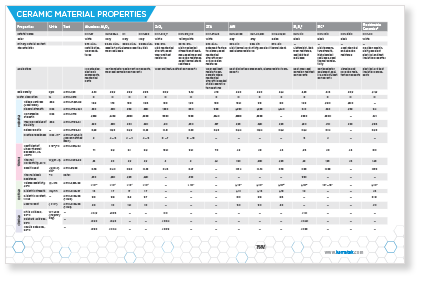

Ceramic Materials Properties Chart — All Materials — PDF, 128K

For more information or to get a quote on your next refurbishment project, please contact us.