![]()

Silicon Nitride — Si3N4

Silicon nitrides have a unique grain structure which delivers both high strength, toughness and very good thermal shock resistance — making it ideal for applications with high dynamic stresses, thermal stress, and high reliability requirements. This unique combination of material properties provides advantages in severe-service applications such as turbines and high-end ball bearings.

Primary Features

- Wear resistance

- Corrosion resistance

- High mechanical strength and toughness

- Electrically insulating

- Thermal shock resistance

Applications

- Wear-resistance components

- Semiconductor manufacturing equipment components

- High-temperature components

![]()

![]()

![]()

Material

- KMT-SiN — Si3N4 (black)

Material Properties for KemaTek™ Silicon Nitride

| Properties | Units | Test | Silicon Nitride — Si3N4 |

| Material Name | KMT-SiN | ||

| Color | Black | ||

| Primary Material Content | — | ||

| Characteristics | Lightweight, high wear resistance, and high heat resistance | ||

| Applications | Heat, wear, and corrosion-resistant components | ||

| Bulk Density | g/cc | ASTM-C20 | 3.20 |

| Water Absorption | % | ASTM-C373 | 0 |

| Vickers Hardness (Load 500 g) | GPa | ASTM-C1327-03 | 13.9 |

| Flexural Strength | MPa | ASTM-C1161-02c | 610 |

| Compressive Strength | MPa | ASTM-C773 | 3850 |

| Young’s Modulus of Elasticity | GPa | ASTM-C1198-01 | 290 |

| Poisson’s Ratio | — | ASTM-C1198-01 | 0.28 |

| Fracture Toughness | MPa * m12 | ASTM-C1421-01b (Kevron notched beam) | 5 |

| Coefficient of Linear Thermal Expansion, 40-400 ℃ | x 10-6/℃ | ASTM-C372-94 | 2.6 |

| Thermal Conductivity, 20℃ | W/(m • K) | ASTM-C408-88 | 23 |

| Specific Heat | J/(Kg • K) x 103 | ASTM-E1269 | 0.66 |

| Thermal Shock Resistance | ℃ | Note 1 | 550 |

| Volume Resistivity, 20℃ | Ω • cm | ASTM-D257-99 | ≥1024 |

| Dielectric Strength | KV/mm | ASTM-D149-97 | 13 |

| Dielectric Constant, 1 MHz | — | ASTM-D150-98 (1 MHz) | — |

| Loss Tangent | (x 10-4 | ASTM-D150-98 (1 MHz) | — |

| Nitric Acid 60% 90℃ | WT Loss (mg/cm2/day) | — | < 1.0 |

| Sulphuric Acid 95%, 95℃ | WT Loss (mg/cm2/day) | — | < 0.40 |

| Caustic Soda 30%, 95℃ | WT Loss (mg/cm2/day) | — | < 0.36 |

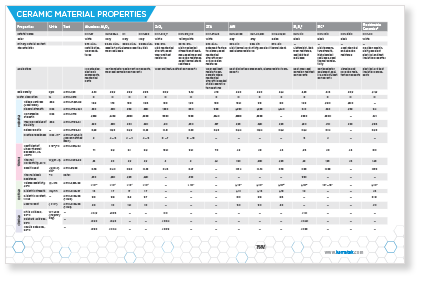

Ceramic Materials Properties Chart — All Materials — PDF, 128K

For more information or to get a quote on your next refurbishment project, please contact us.