Zirconium Oxide ZrO2

Known for their high mechanical strength and fracture toughness, zirconias are ideal for extreme mechanical environments, particularly impact prone applications. Certain zirconia compositions provide enhanced fatigue loading resistance.

Zirconias are toughened with the addition of Yttria (Y) or Magnesium Oxide (MgO) to exhibit different properties. Yttria-stabilized zirconia’s best strengths include exceptional toughness, flexural strength, and high-temperature stability. Magnesia-stabilized zirconia are commonly selected for severe-duty applications.

Primary Features

- High mechanical strength

- Enhanced fracture toughness (impact resistance)

- Mechanical strength

- High-heat resistance

- Thermal expansion near metal

- Corrosion resistance

- Natural lubricity

Applications

- Wear-resistant components

- Mechanical components

- Tools and molds

- Fluid handling

- Heat insulation material

![]()

Materials

- KMT-ZrO2 — 95% ZrO2 (white)

- KMT-ZrO2Mg — 96.5% ZrO2 (yellow/white)

Material Properties for KemaTek™ Zirconias

| Properties | Units | Test | Zirconias — ZrO2 | |

| Material Name | KMT-ZrO2 | KMT-ZrO2Mg | ||

| Color | White | Yellow/White | ||

| Primary Material Content | 95% ZrO2 | 96.5% ZrO2 | ||

| Characteristics | High mechanical strength, good wear and heat resistance | High mechanical strength and toughness, good wear and corrosion resistance. Good thermal shock resistance | ||

| Applications | Wear and heat-resistant components | |||

| Bulk Density | g/cc | ASTM-C20 | 6.02 | 5.72 |

| Water Absorption | % | ASTM-C373 | 0 | 0 |

| Vickers Hardness (Load 500 g) | GPa | ASTM-C1327-03 | 13.0 | 12.0 |

| Flexural Strength | MPa | ASTM-C1161-02c | 1250 | 900 |

| Compressive Strength | MPa | ASTM-C773 | 5690 | 1900 |

| Young’s Modulus of Elasticity | GPa | ASTM-C1198-01 | 210 | 200 |

| Poisson’s Ratio | — | ASTM-C1198-01 | 0.31 | 0.30 |

| Fracture Toughness | MPa * m12 | ASTM-C1421-01b (Kevron notched beam) | 6 — 7 | 9 — 10 |

| Coefficient of Linear Thermal Expansion, 40-400 ℃ | x 10-6/℃ | ASTM-C372-94 | 10.0 | 9.0 |

| Thermal Conductivity, 20℃ | W/(m • K) | ASTM-C408-88 | 3 | 3 |

| Specific Heat | J/(Kg • K) x 103 | ASTM-E1269 | 0.46 | 0.47 |

| Thermal Shock Resistance | ℃ | Note 1 | — | 350 |

| Volume Resistivity, 20℃ | Ω • cm | ASTM-D257-99 | — | ≥1011 |

| Dielectric Strength | KV/mm | ASTM-D149-97 | — | — |

| Dielectric Constant, 1 MHz | — | ASTM-D150-98 (1 MHz) | — | — |

| Loss Tangent | (x 10-4 | ASTM-D150-98 (1 MHz) | — | — |

| Nitric Acid 60% 90℃ | WT Loss (mg/cm2/day) | — | 0.0 | — |

| Sulphuric Acid 95%, 95℃ | WT Loss (mg/cm2/day) | — | <0.04 | — |

| Caustic Soda 30%, 95℃ | WT Loss (mg/cm2/day) | — | <0.08 | — |

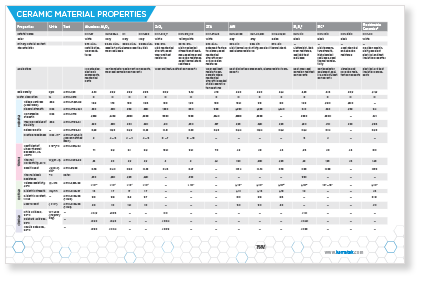

Ceramic Materials Properties Chart — All Materials — PDF, 128K

For more information or to get a quote on your next refurbishment project, please contact us.